Organic fertilizer cow dung compost round pellet machine

Model : | KHL-500 |

Capacity: T/h | 2-2.5 |

Input moisture content required: % | 30-35 |

Moisture reduce after granulation : % | 3 |

Input material particle size required : mm | 0.3-0.5 |

Rate of finished products:% | >90 |

Voltage : V | 380 (optional) |

Granules size: mm | 3.5-5.5 |

Power: KW | 56.5 |

Total weight:Kg | 3000 |

Size: m | 4.5-1.6-1.4 |

The series of granule machines can make the following raw materials into granules :

1. Turfs, lignite, sludge, pond sludge,Sucrose slag,starch pulp as materials can be made into granules;

2. Chicken manure ,duck manure , pig manure , sheep dung , deer manure ,cow dung and earthworm cast as materials can be made into granules ;

3. Bean cakes ,Vinasse slag, Biogas residue , Fruit residue ,palm oil residue as the main materials can be made into granules;

4. Residues of urban rubbish or sewage treatment plants as materials can be made into granules.

5. Organic materials mix with mineral materials .

Organic fertilizer cow dung pellet machine

Working Principle

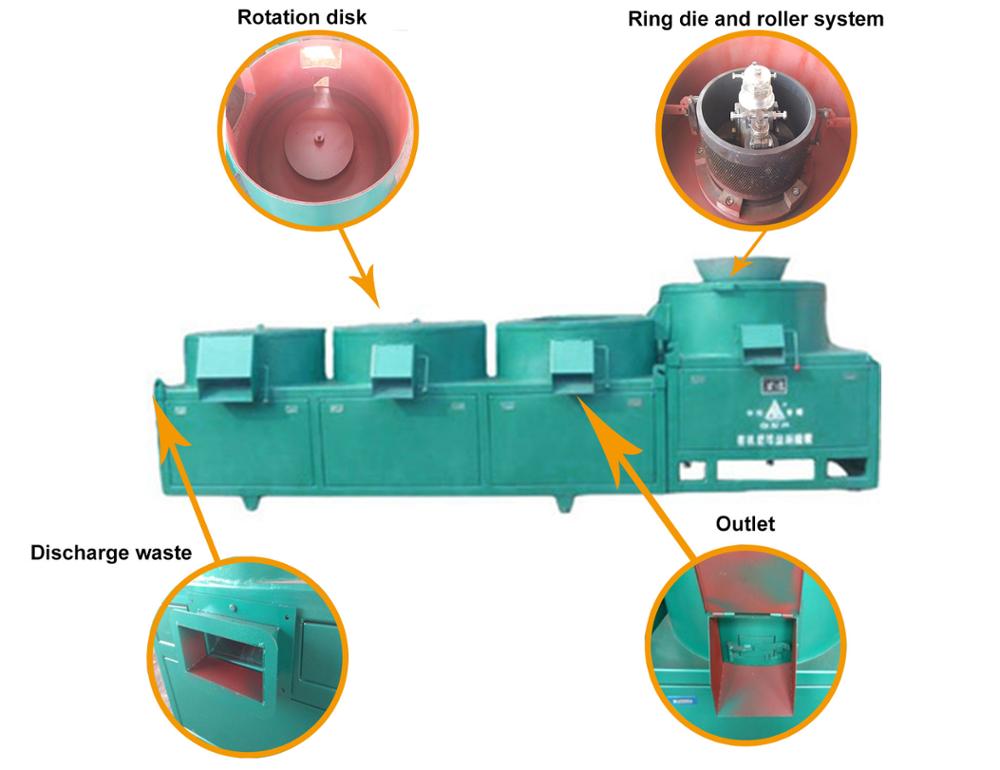

The Organic fertilizer cow dung pellet machine has two parts :

1, Pelletizer part

2, Polisher (Balling) part

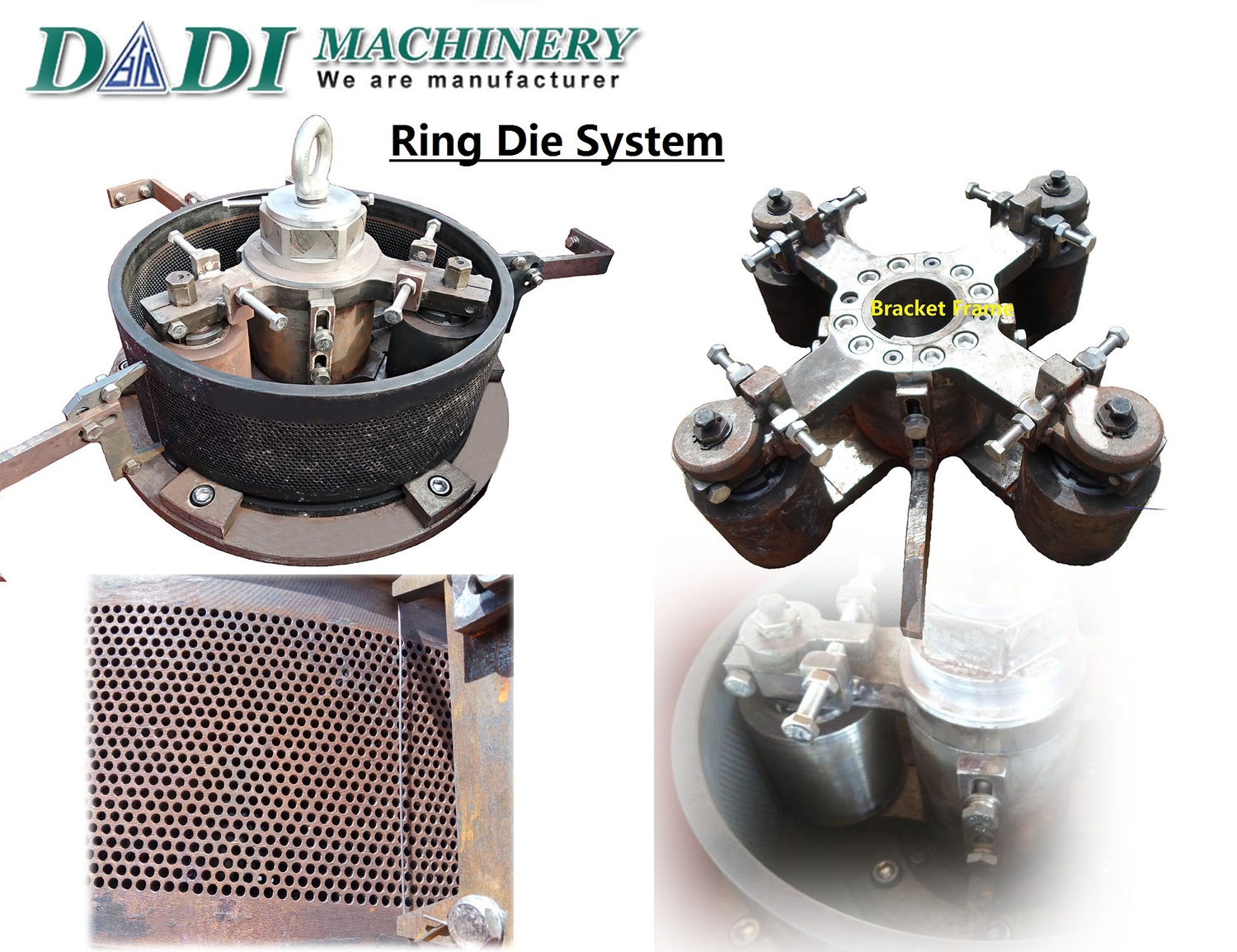

The Pelletizer part with Ring die and rollers system :

The raw material goes into working chamber and fall on the ‘dump tray’, the raw materials throw into the ring die by centrifugal effect ; The ring die and rollers system turning drive by reduction gears & transmission which energy from motor . The pressure come from ring die and rollers system running ,cylinder form are forced extrusion from ring die hole ,which cutting into small pellets as required by cutting line .

Polisher (Balling) part are rotation disks :

The small pellets fall onto the disk in the drum ,by high-speed rotating disk throw onto the wall of drum with circumferential movement , the granules in a circular motion at the same time also in radial rotation motion due to centrifugal effect . Mutual friction make the granules with edges and corners into balls gradually due to granules’ moving . At this moment , Polisher (Balling) part gradually floating on the top , final granules overflow along with quantity of granules increased in the drum .

Organic fertilizer cow dung pellet machine

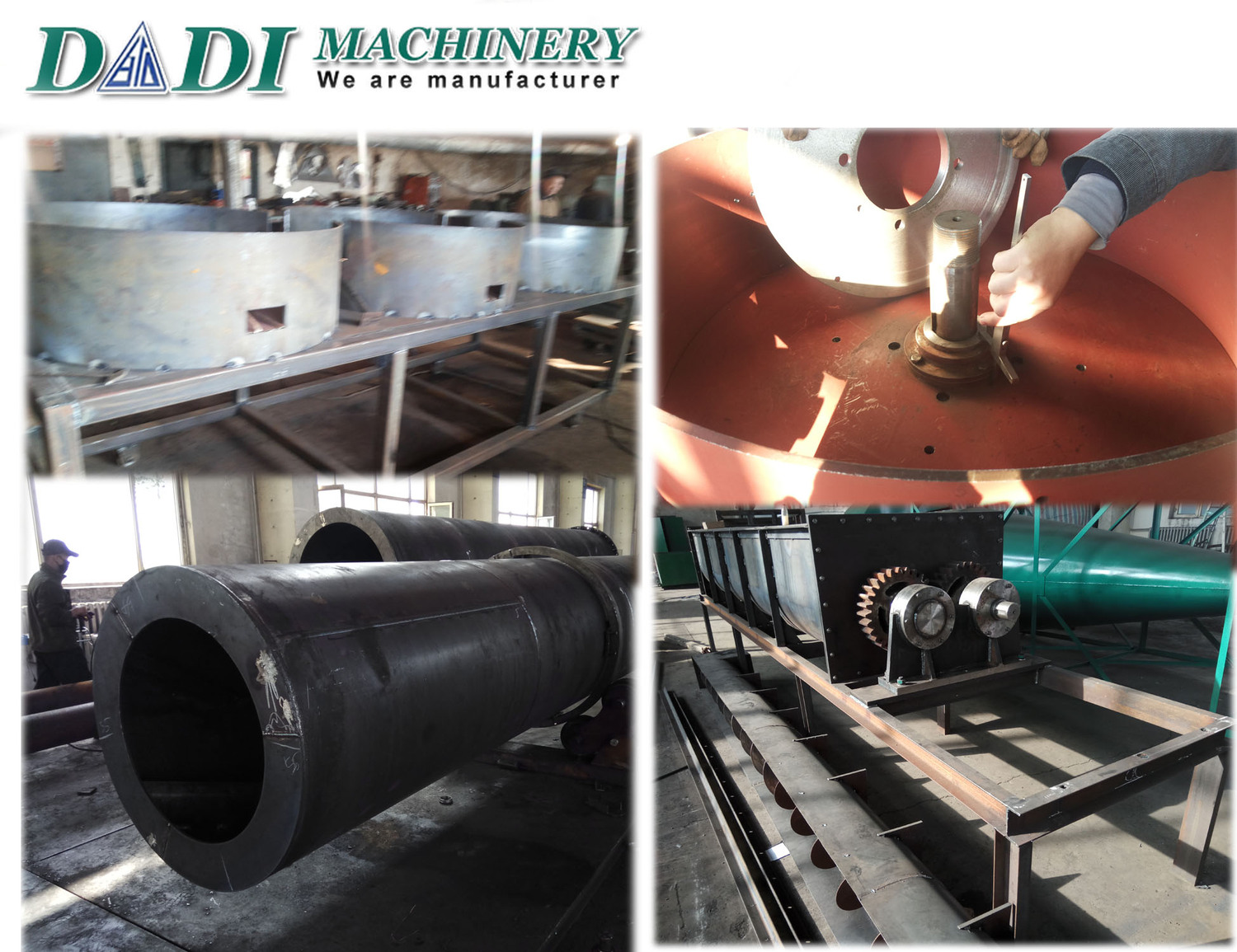

Organic fertilizer cow dung compost round pellet machine from Harbin Dadi Machinery

Allow me to outline some key advantages of our organic fertilizer pelletizer:

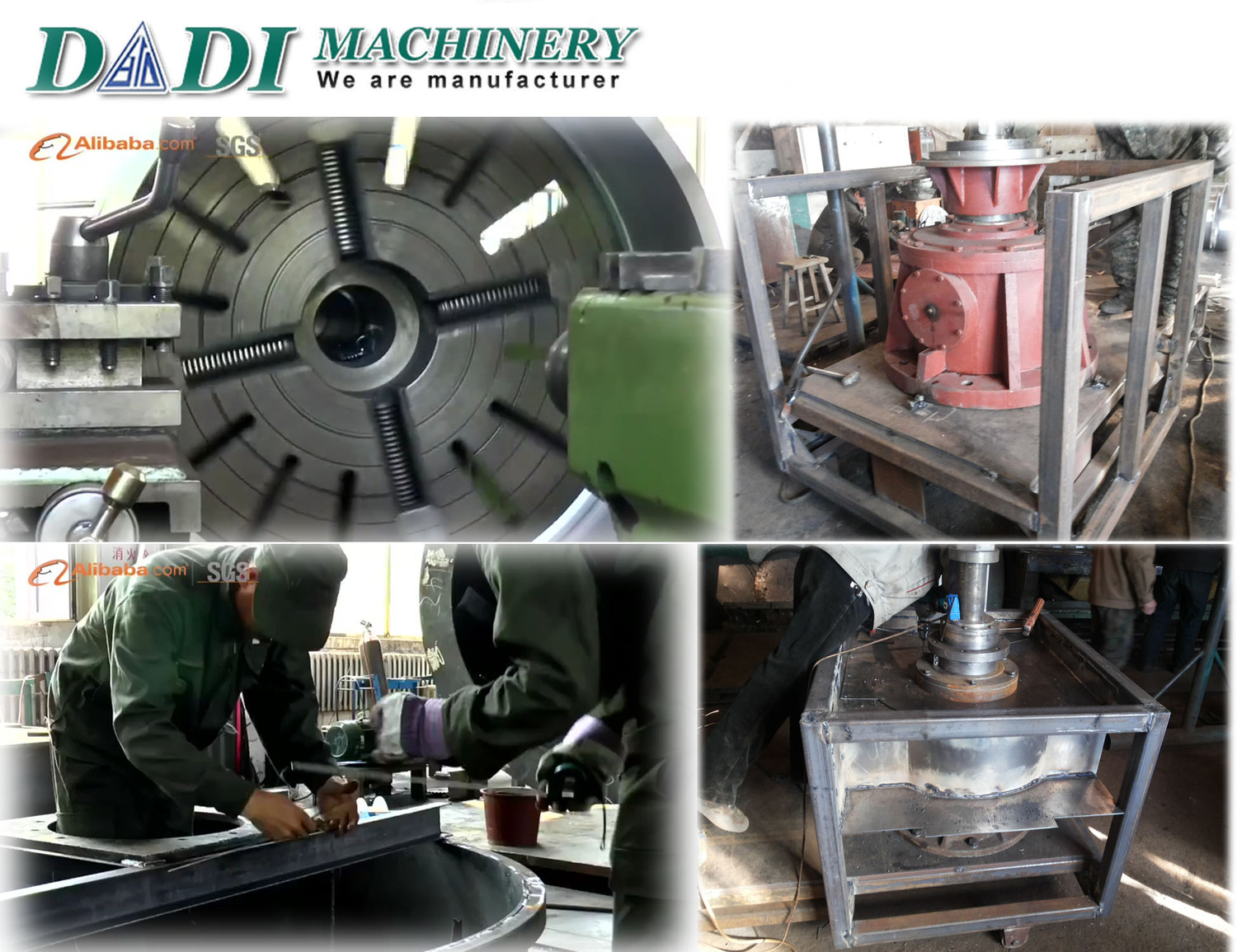

1. Advanced Technology: Our machine incorporates the latest and most advanced technology, ensuring precise and consistent pellet production. It maximizes the utilization of raw materials and minimizes waste, resulting in optimal efficiency.

2. Superior Pellet Quality: The organic fertilizer pellets produced by our machine boast excellent uniformity, hardness, and durability. This ensures consistent nutrient release and absorption for enhanced crop growth and yield.

3. Versatility and Adaptability: Our machine is versatile and can process a wide range of organic materials, including plant residues, animal manure, compost, and more. It is capable of adjusting to various moisture levels, ensuring consistent pellet quality regardless of feedstock variations.

4. User-Friendly Interface: Our organic fertilizer pelletizer features a user-friendly interface, making it easy to operate and monitor. With minimal training, your team can quickly adapt to and operate the machine efficiently.

5. Cost-Effectiveness: Our machine is designed with cost-effectiveness in mind. It optimizes energy consumption, reduces maintenance requirements, and ensures long-term reliability. This translates into significant savings and a higher return on investment for your business.

At Harbin Dadi Machinery, we are committed to delivering top-notch equipment and exceptional customer service. We strive to exceed our clients' expectations, providing them with reliable and innovative solutions to meet their fertilizer production needs.

I would be delighted to provide you with further information, discuss your specific requirements, or arrange a demonstration of our organic fertilizer pelletizer. Please feel free to reach out to me at your convenience.

Thank you for your time and consideration. I look forward to the opportunity of serving you and establishing a successful business relationship.